JetSkiTech

JET SKI REBUILDERS

JetSkiTech

JET SKI REBUILDERS

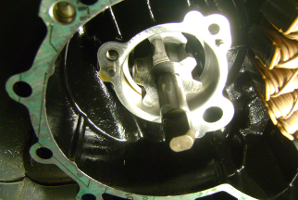

Jetskitech offers a thorough rebuild process that goes beyond disassembly, machining and refitting. The pump gear shaft is often overlooked in the jet ski rebuild process. We throughly inspect and/or replace the oil pump and shaft to ensure you get a professional repair job.

image thanks to m123207 creative commons licence

Jetskitech goes the extra mile by degreeing your camshaft to correct for tolerances in the machining processes of the engine that can affect camshaft timing. Jetskitech uses the intake centerline method as it is the most efficient way to degree a new or re-used jet ski camshaft.

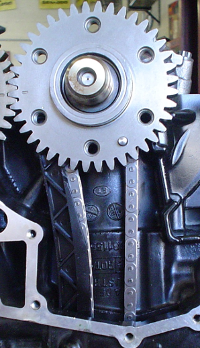

Timing chain installations are crucial to perfect engine operation. Jetskitech recommends replacement of tensioners and gears with each rebuild to ensure your rebuilt jet ski engine performs to specs and to ensure reliability. We use the highest quality cam lube in the installation process.

Jetskitech recommends replacement of pistons on every rebuild job unless the customer insists on re-using pistons for cost-containment purposes. Whether new or used, the installation process for your jet ski is the same, with liberal use of high-quality lubricants.

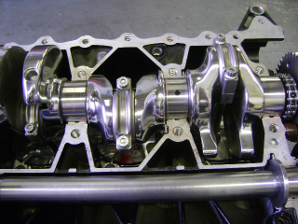

Major jet ski engine rebuilds include crankshaft balancing and blueprinting, end clearance checks and the use of high quality bearings and replacement bolts where necessary. Jetskitech ensures your crank will perform as expected, provided you follow proper riding procedures.